The next project I have planned for my hyrel is going to take a really long time to print, so I’m planning on leaving that one for the weekend! However, I did some work on my Kossel delta printer in the meantime. I tried printing a bigger piece, and I realized that the bed of the printer wasn’t level, and no amount of auto leveling would fix it! So what was the solution? Washers.

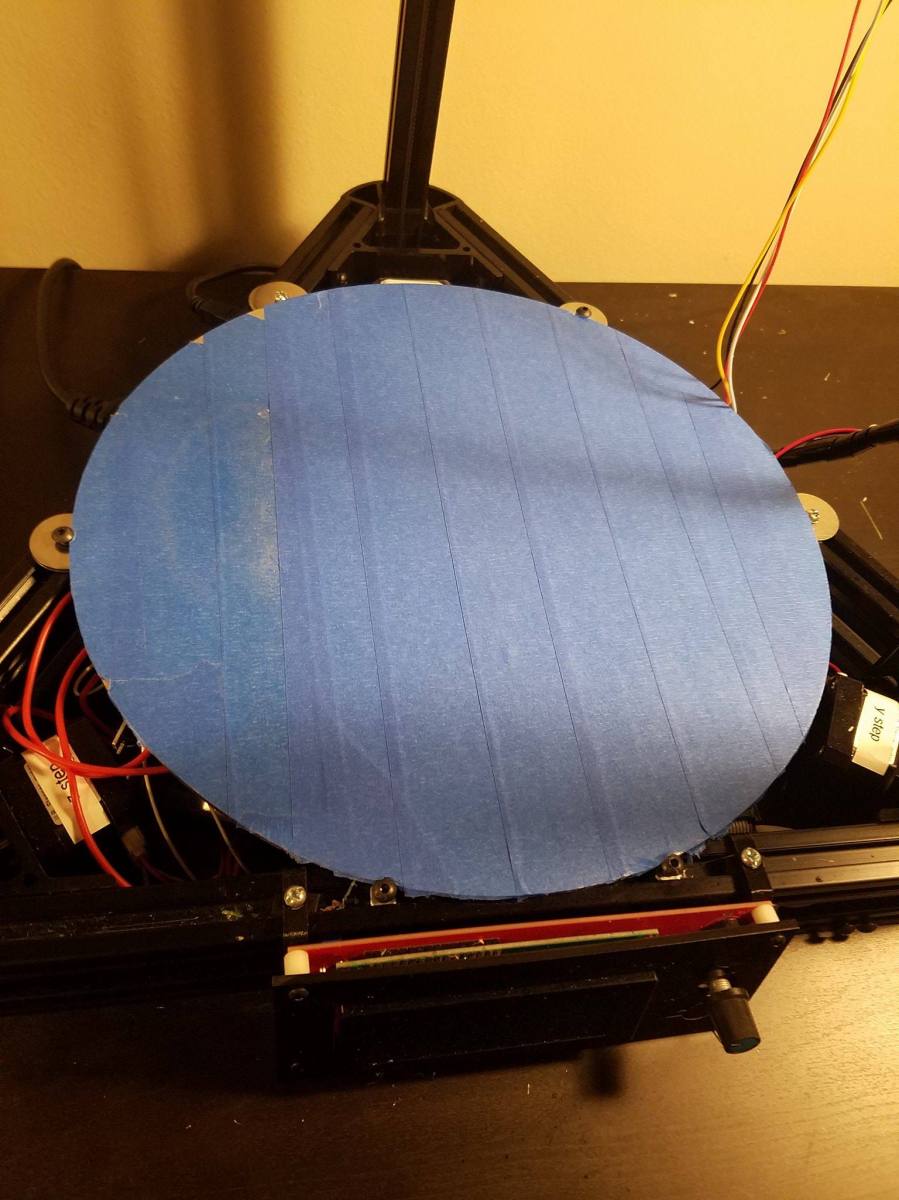

I bought some washers and used them as spacers to jack the platform up! very simple solution, and it actually worked! Here’s what the printer bed looks like now:

Some sides of the plate needed two washers, while others only needed one, but it evened everything out for sure! Now that I took care of the sticking issue, I noticed something else… it was failing part way up and extruding so stringy that it couldn’t build successive layers on top of each other… There are two things that I’m going to play with to test what’s going on:

1.) A higher feed rate or flow rate (or both!)

2.) A different filament holding system that offers less resistance

either one of those things could potentially be the problem, so we’ll see what fixes it! I’m almost at the point of having another perfect printer now… just have a little bit more work to do, so stay tuned!

John (aka The Mad Printer)

http://www.thingiverse.com/thing:373064

http://www.thingiverse.com/thing:1666487

LikeLike