This one is mine, and I’m so excited! I finally got my hands on the Hyrel Engine I will be completing all of my projects on from now on:

For the future of the blog, I’m going to focus on the experience of printing with Hyrel printers! Some of the projects will be focused on dialing in new materials and getting them to print on the Hyrel (since it can print any material with a little TLC and adjusting of settings!!). Other projects will be focused on completing cool projects that show the printer off!

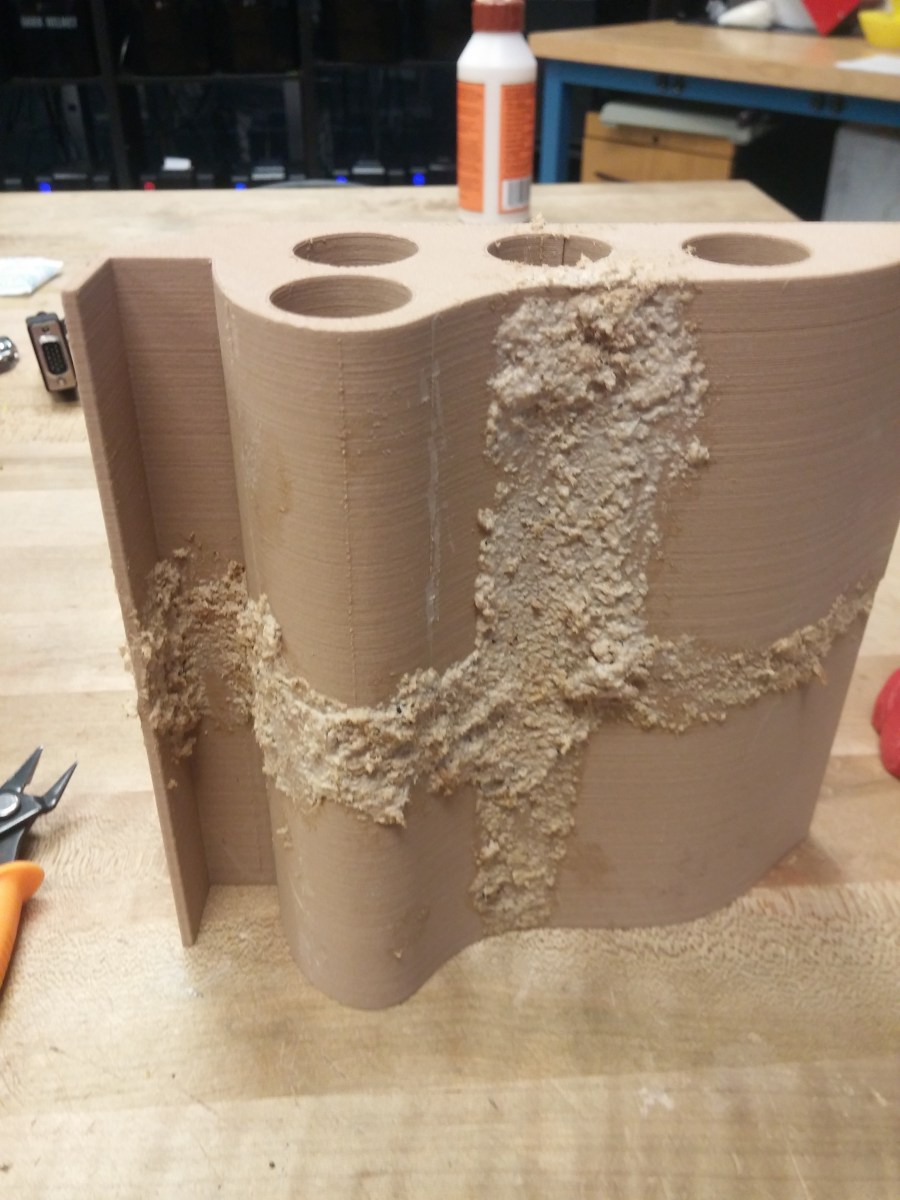

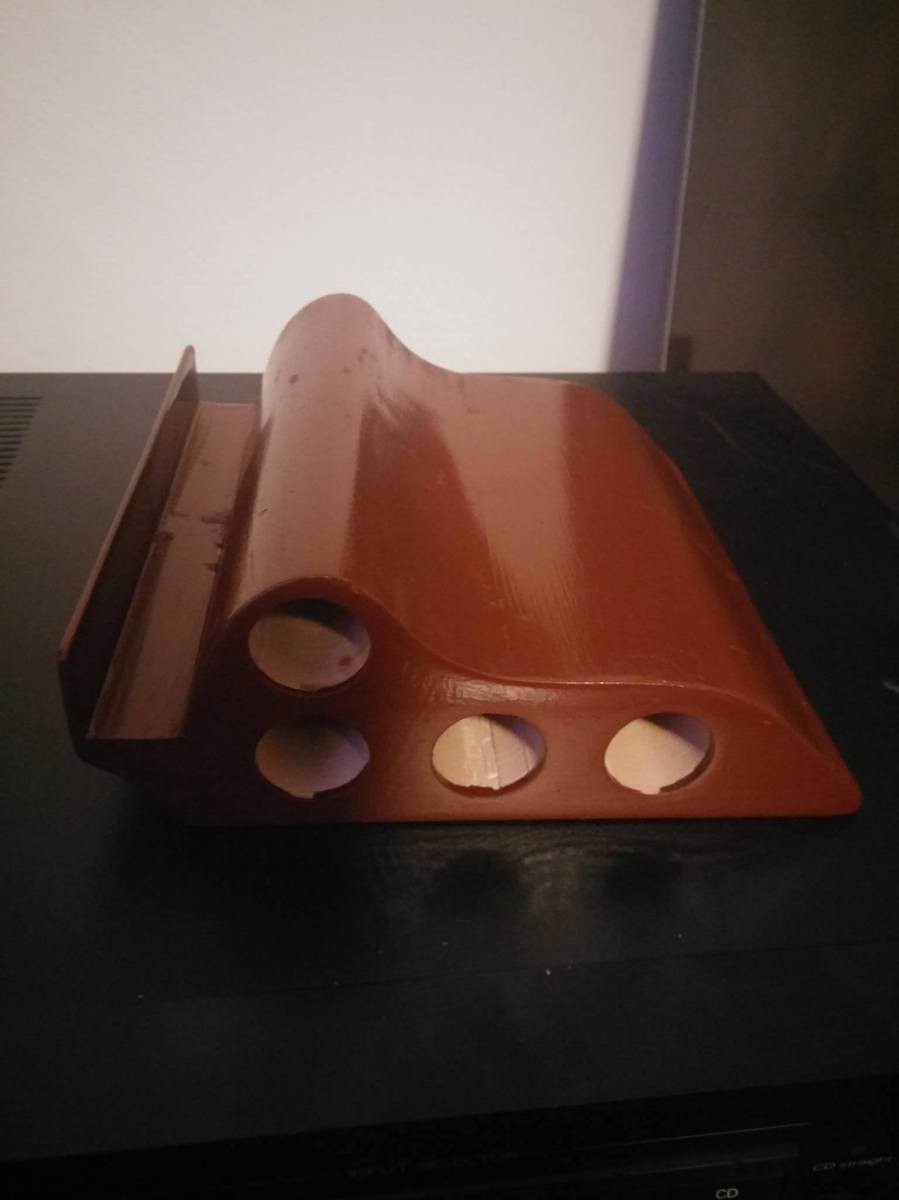

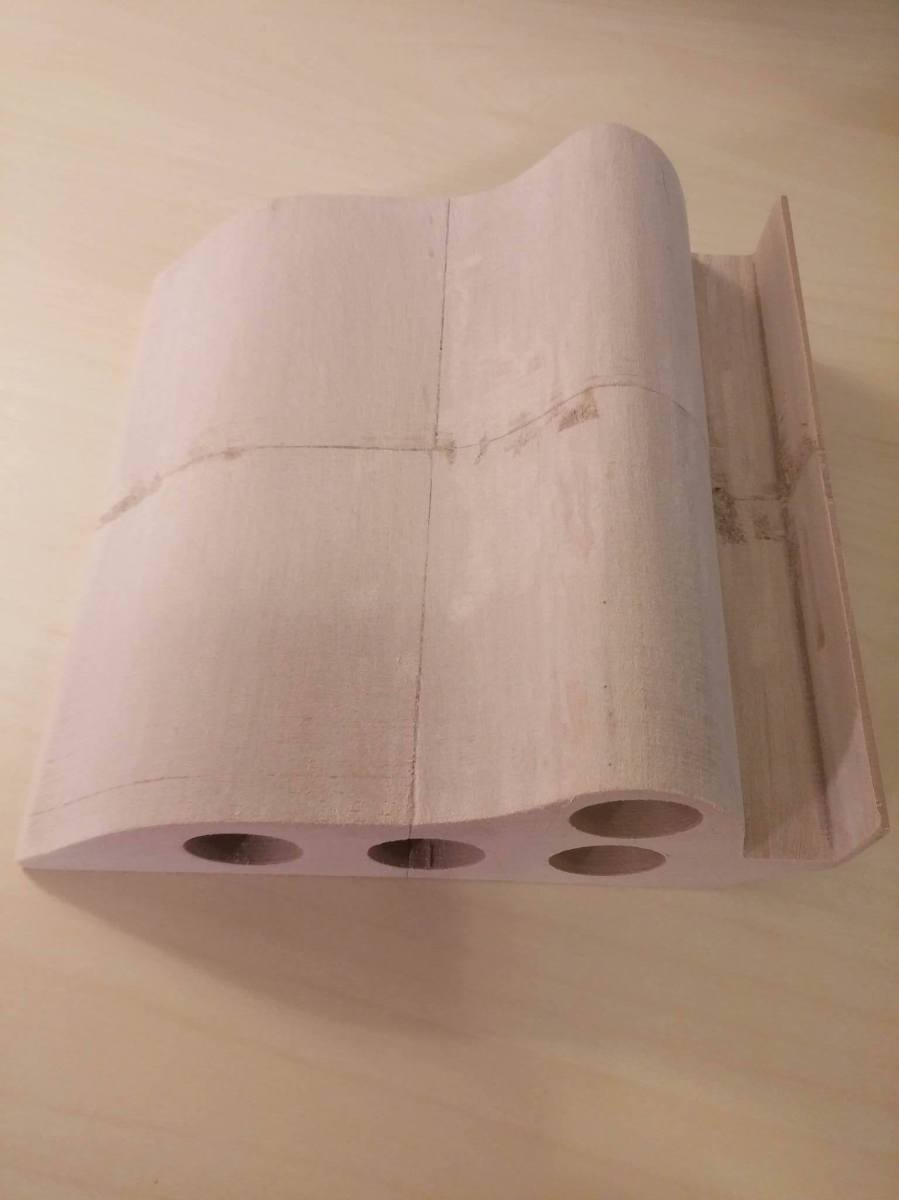

You can see the first project in the above picture! The Hyrel has 2 side clips that were meant to hold extra heads, but I cadded a block that holds a 3/4″ diameter PVC pipe assembly and that clips into the side clips on the hyrel. It looks a little lopsided because of the angle of the picture, actually. When you take the picture straight on, it looks a lot better haha. My main reason for adding the PVC pipe assembly is to hang filament above the head! There are some filaments that are very brittle (wood filled PLA, Brass filled PLA, machinable wax filament, etc), and print much better when gravity assists their feeding into the head. suspending filament dramatically changes printing in my experience because it facilitates easier flow when the printer doesn’t have to pull the filament in as hard.

When you dial in new filaments, there are a whole bunch of settings that you have to keep in mind in order to get perfect filament flow through the nozzle! Pulses per nanoliter, feed rate, prime and unprime settings (steps, speed of steps, time), fan settings, flow rate, head temperature, and bed temperature).

The “pulses per nanoliter” setting adjusts the number of pulses of the extruder stepper motor per nanoliter of plastic extruded through the nozzle. The “feed rate” setting adjusts the amount of nanoliters fed through the nozzle. For the prime/unprime settings, the “steps” setting adjusts the number of steps from the stepper motor for the unprime (retract) or the prime (extrude after retract), the “speed of steps” setting adjusts the speed at which the prime/unprime steps from the stepper motor happen, and the “time” setting adjusts the amount of time the head movement pauses while the prime/unprime event is happening (in milliseconds).

Of course, different materials have different base temperatures and cooling requirements. For example, ninjaflex needs about 40-50% fan depending on the size of the part, while PLA only needs about 30% fan. different materials also extrude at different temps (240-ish for ninjaflex, 212-ish for PLA), and different materials require different bed temps to be able to print well without any layer separation.

The last factor is flow rate, which is controlled through slic3r, the software on Hyrel’s printers that makes an STL printable. This also controls the amount of flow through the nozzle in addition to the flow rate.

So all the different settings combine to make the magic formula that allows plastic to become 3d printed things! My next post will be about using all those settings to dial in a material so you guys can see the process that I go through! I’ll keep you posted.

John (aka the Mad Printer)

It was definitely an interesting experience for sure! The nice thing about the stain is it hides all those glue seams completely! It worked super well.

It was definitely an interesting experience for sure! The nice thing about the stain is it hides all those glue seams completely! It worked super well.

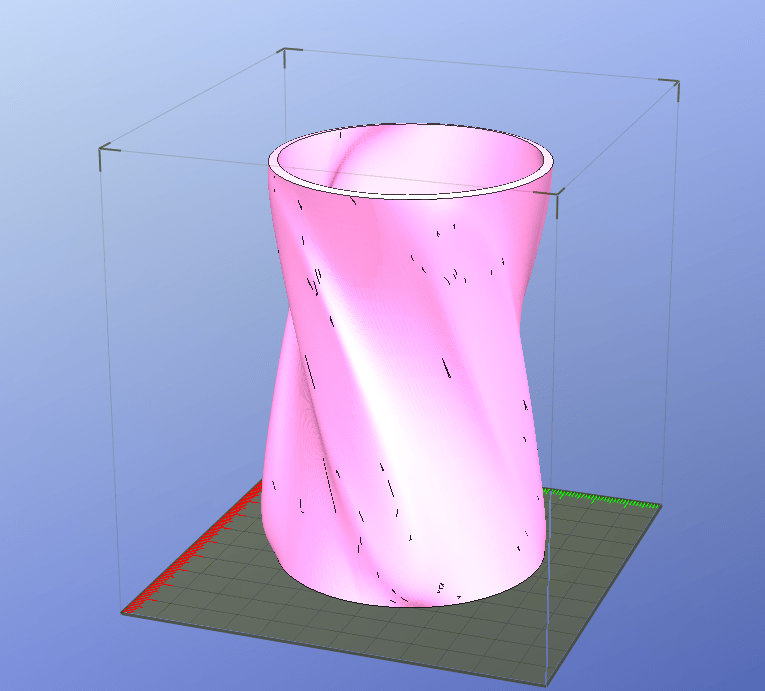

Upon seeing this picture, you notice a few things:

Upon seeing this picture, you notice a few things: